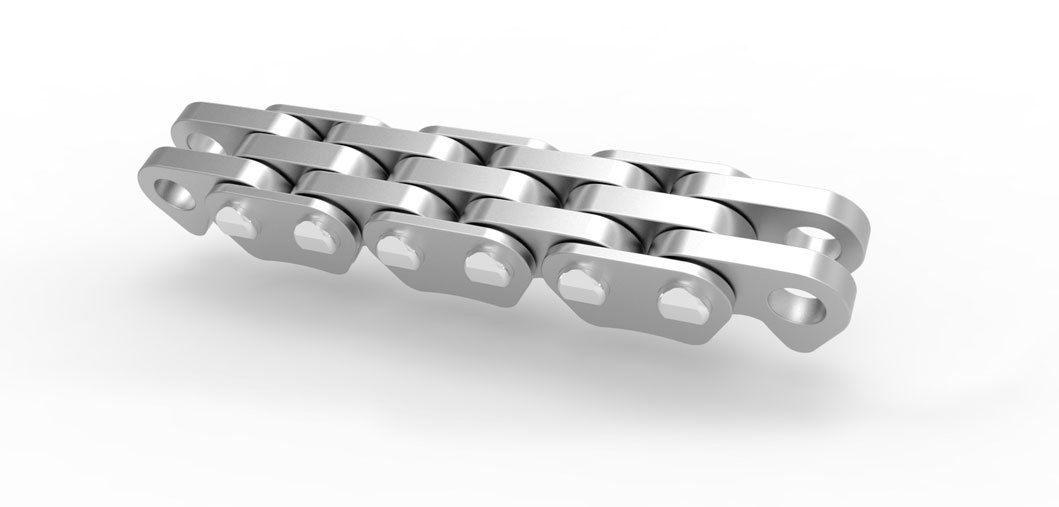

R&D Technology

because every chain system is unique

Catensys is integrated into the customer’s value chain due to unparalleled R&D capabilities, covering systems engineering, development, testing and return part analysis, as well as product design. We work closely with our customers from application engineering, development, testing and return part analysis to product design. Catensys holds over 150 patents and, being dedicated to chains, will foster this innovative spirit for the benefit of our customers.

Here are a few of our latest product innovations and improvements giving you a distinct advantage: