Agile and Hands on

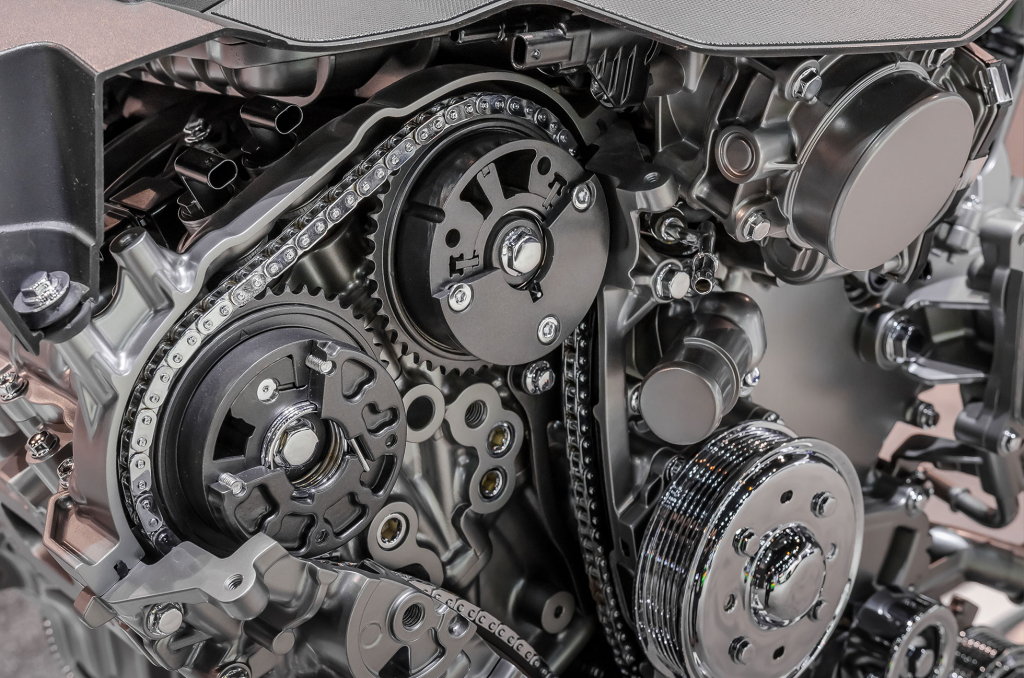

The dedicated team that has earned the trust of the motor manufacturing industry for more than 30 years is now more agile, more flexible and as reliable as ever. We place emphasis on being responsive or, indeed, pro-active as well as uncomplicated, so that our customers’ experience with Catensys is the same as our chain drive systems: smooth and efficient.

Many suppliers have fragmented their efforts with a variety of products but only Catensys stays true only to chain drive systems. This is one of the reasons that, when our customers need the best solutions, that’s exactly what we deliver. We will support your process from the design release engineering stage right up to the after-market.