Chain Drive Systems

it’s what we do

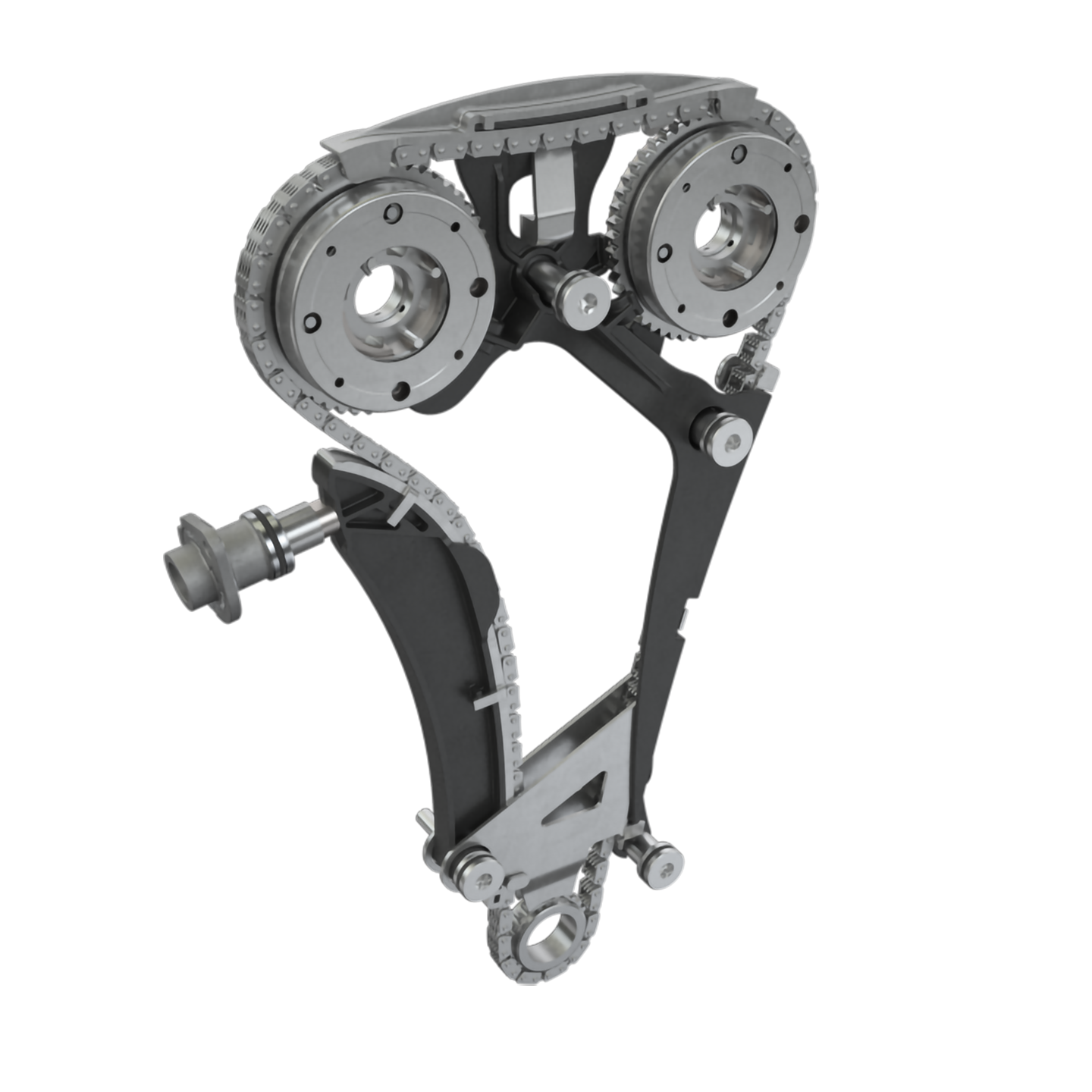

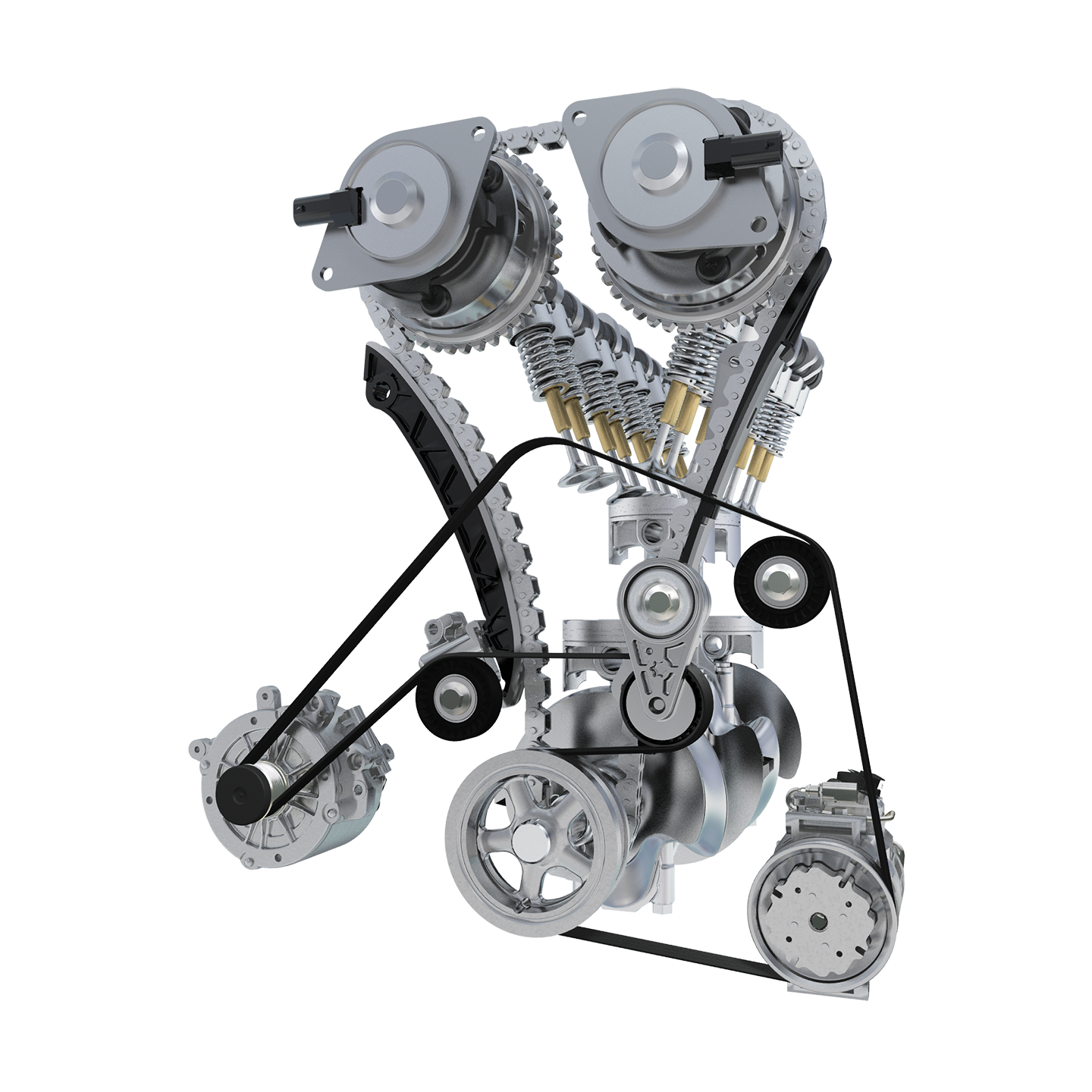

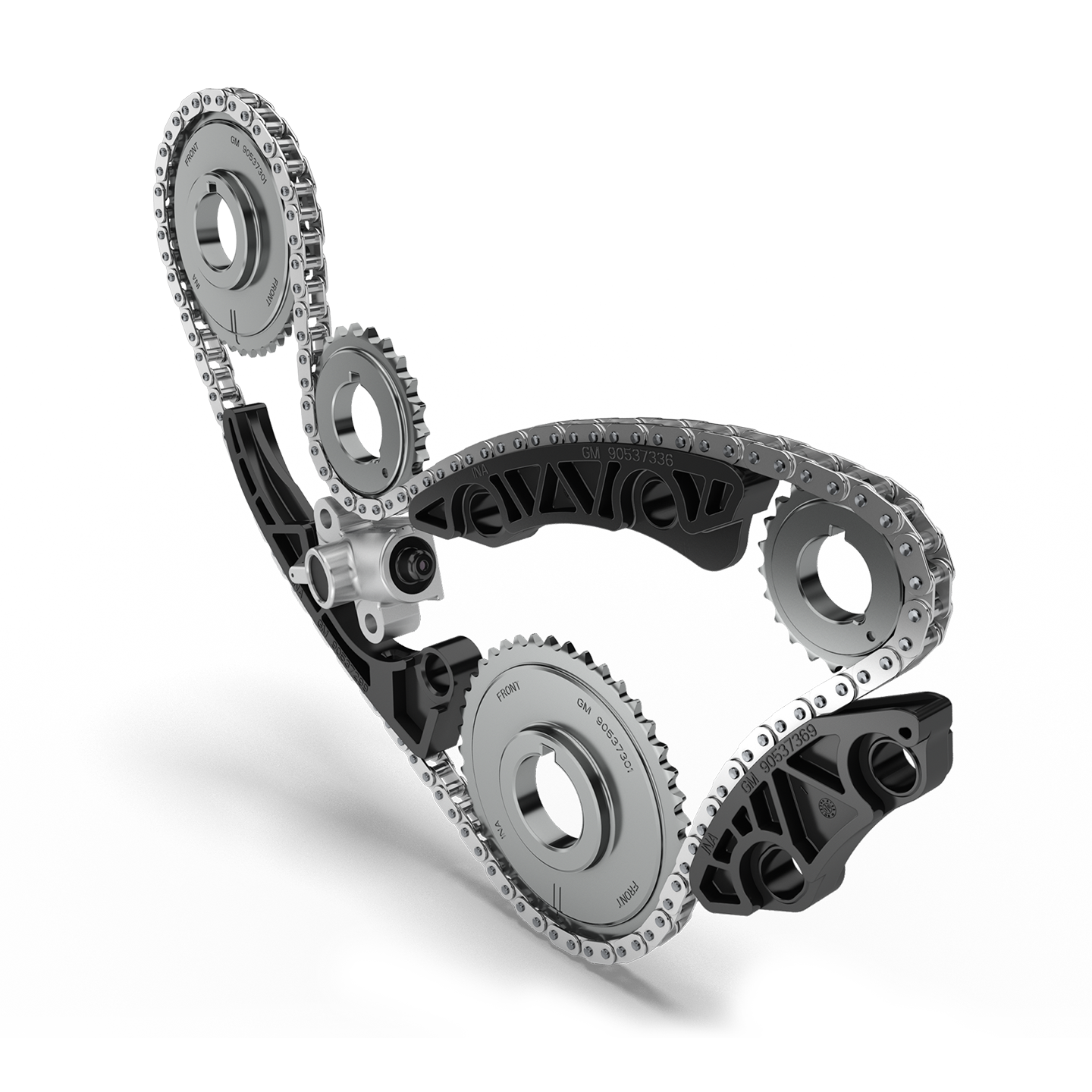

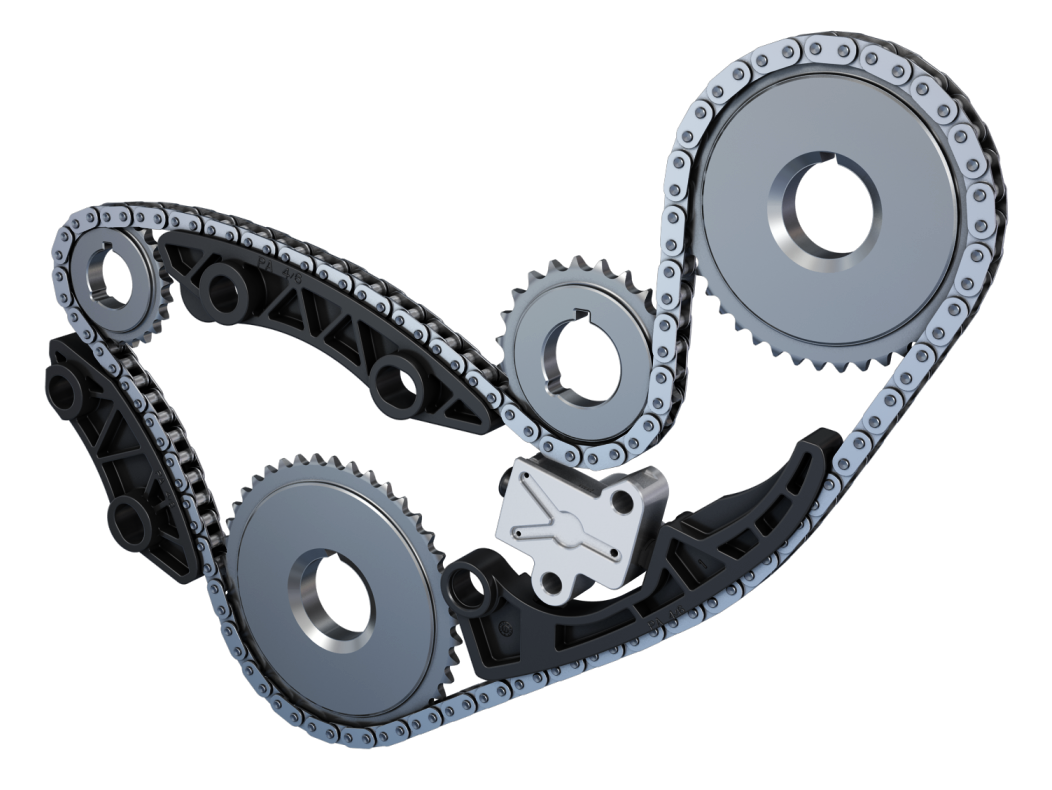

Catensys manufactures chain drive systems for any vehicle using combustion and/or hybrid engines with six key elements in mind: sound, weight, durability, precision, friction and costs.

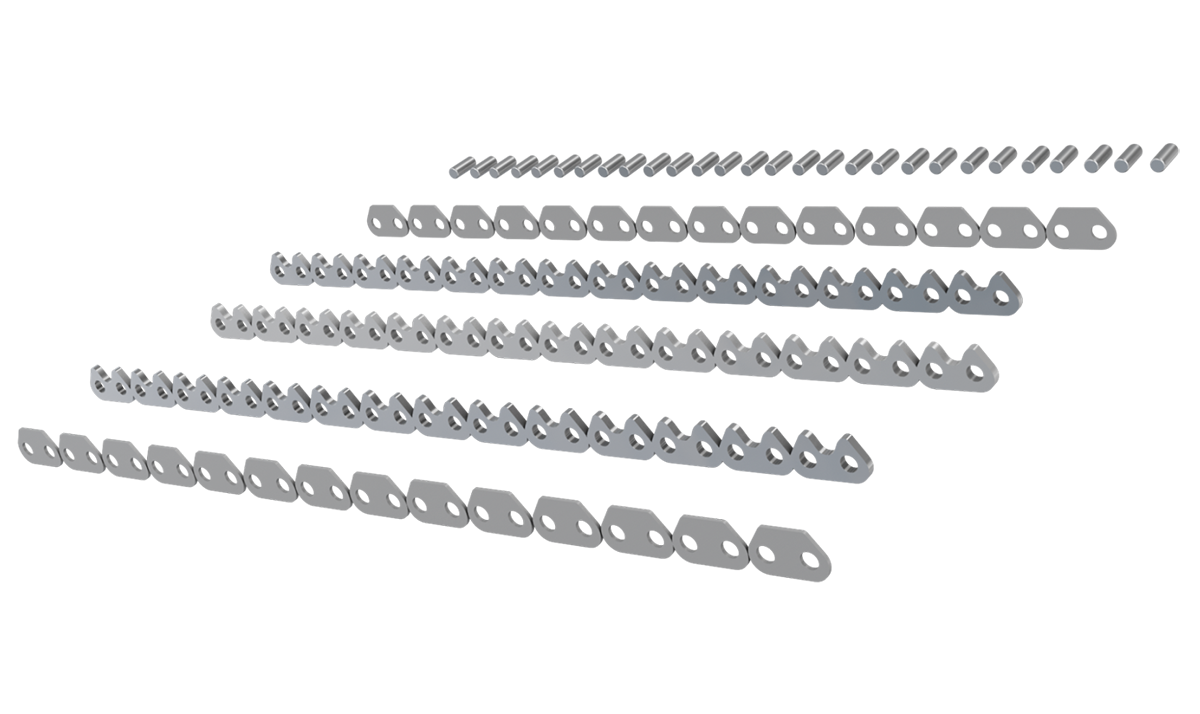

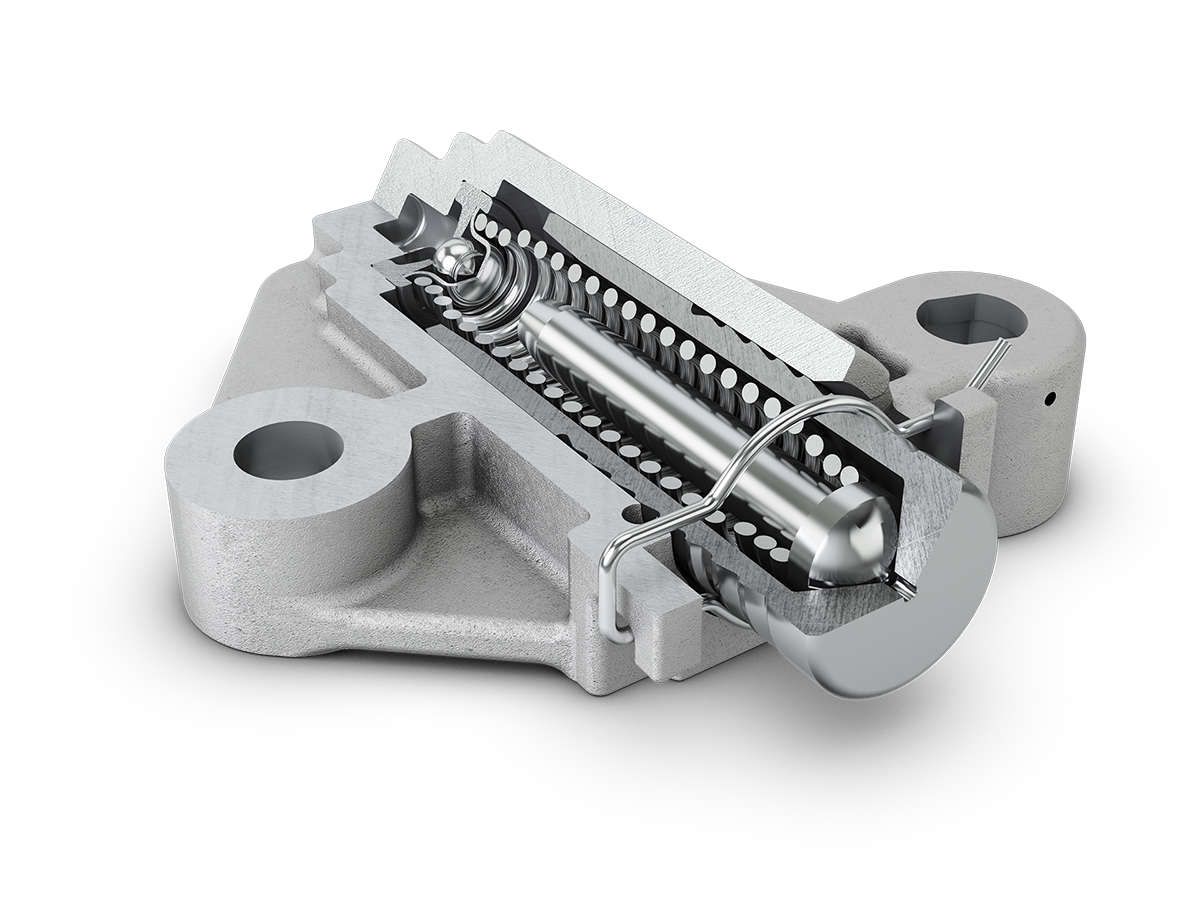

Each link in each chain, each tensioner, guide and sprocket is a result of extensive know how, many years of experience and active R&D. Focusing on our customers’ challenges we have developed and keep improving our high quality products which specifically feature low noise and friction, high durability, temperature resistance and a very competitive cost:performance ratio.

Catensys has a comprehensive range of high-quality components for any customized chain drive systems: